Shutting the Door on Dust

April 1, 2019 / General, 101 learning, Upgrading and troubleshooting, Best Practices

We know we talk a lot about fiber cleanliness, but let’s face it, contamination of fiber endfaces is still the number one cause of failures – regardless of much we harp on the topic.

You’ve probably often also heard comments surrounding the fact that dust caps are really just dust collectors. Thankfully, there are plenty of manufacturers out there that get it and have responded with shuttered fiber connectivity.

The Dreaded Dust Cap

Regardless of the type of fiber, application or data rate, the transmission of light requires a clear pathway along a link, including through any passive connections or splices along the way. A single speck of dust on the core of a fiber that’s invisible to the human eye can cause loss and reflections, resulting in high error rates and degraded network performance. Contamination on a fiber endface can also adversely impact the interface of expensive optical equipment, and in some cases even render equipment inoperative.

You might be feeling thankful that your fiber connectivity components arrive in what looks like nice clean packaging protected by a small white (sometimes beige) dust cap to protect the endface from damage and supposedly dirt. But even the highest quality manufacturers who factory test each and every fiber connector know that you should still inspect every endface before you make your final connections. That’s because dust caps themselves can be a significant source of contamination.

While dust caps might give the impression of a clean endface, no one can really know for sure what was in that dust cover – even if it came from the factory. While dust caps are great at preventing damage to the endface, did you know that the plastic used to create dust caps can emit a residue as it deteriorates over time and the surface of the cap may contain mold-release substances used in high-speed production processes? In other words, don’t be surprised to find a contaminated endface when inspecting upon removal of a dust cap on a connector fresh out of the bag.

Dust caps are also a nuisance. Every time you plug and unplug from a fiber adapter you’ve got to either remove or replace the dust cap to maintain the endface protection. But those little plastic caps are more often that not dropped on a dirty floor or misplaced altogether, leaving unused ports void of protection and subject to contamination from dust particles in the surrounding environment – especially in the presence of static electricity.

The Revolving Door That’s Also a Window

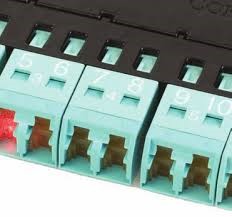

Leading manufacturers today are working to help prevent fiber endface contamination by introducing fiber adapters with integrated shutter doors that allow you to do away with pesky dust caps. While there are a few different versions available, these little shutter doors are designed to move out of the way when a connector is inserted into the adapter – all without ever touching the endface of the connector. With no dust cap to remove, plugging in your fiber jumpers is a faster, cleaner, one-handed operation.

The other great feature of these little shutters is that many of them are transparent enough to let the light from your Fluke Networks’ VisiFault™ Visual Fault Locator shine through – not something you can do with opaque plastic dust caps. That means you can still easily do your tracing and end-to-end fiber link checks with the shutter door closed.

So, the next time you’re ordering fiber adapters, be sure to choose the shuttered feature if it’s available. Many adapters come standard with these shutters, but even if there’s a small upcharge, it’s worth the little extra to protect your fiber deployments – and not have to deal with dust caps.

Golden Rule Still Applies

While we’re a big fan of shuttered fiber adapters, they don’t get you out of the golden rule of inspect, clean and inspect again. And even if you think you have properly cleaned a fiber endface, you still need to follow it. Thankfully Fluke Networks’ FI-7000 FiberInspector Pro accelerates the process by inspecting and certifying endfaces to the IEC 61300-3-35 Basic Test and Measurement Procedures Standard in just over a second.

And in case you haven’t heard, our award-winning FI-3000 FiberInspector™ Pro MPO Inspection Cameraautomates inspection of one or two rows of 8, 12, or 16 UPC or APC style MPO connectors, providing pass/fail results in seconds with an instant live view that gives you the ability to pinch and zoom from full trunk to individual endfaces in real time.